Applications

- Automobile Industry

- Chemical Industry

- Electronics Industry

- Beverages Industry

- Cement Plants

- Spray Painting

- Paper Mills

- Printing & Textile Industry

- Rice and Sugar Mills

- Hospitals

- Tools Room

- Power Plant

- Pet-Blow Moulding

- CNC & CMM Machines

- General Instrumentations

- Pharmaceutical Industry

- and many more...

Refrigerated Compressed Air Dryers

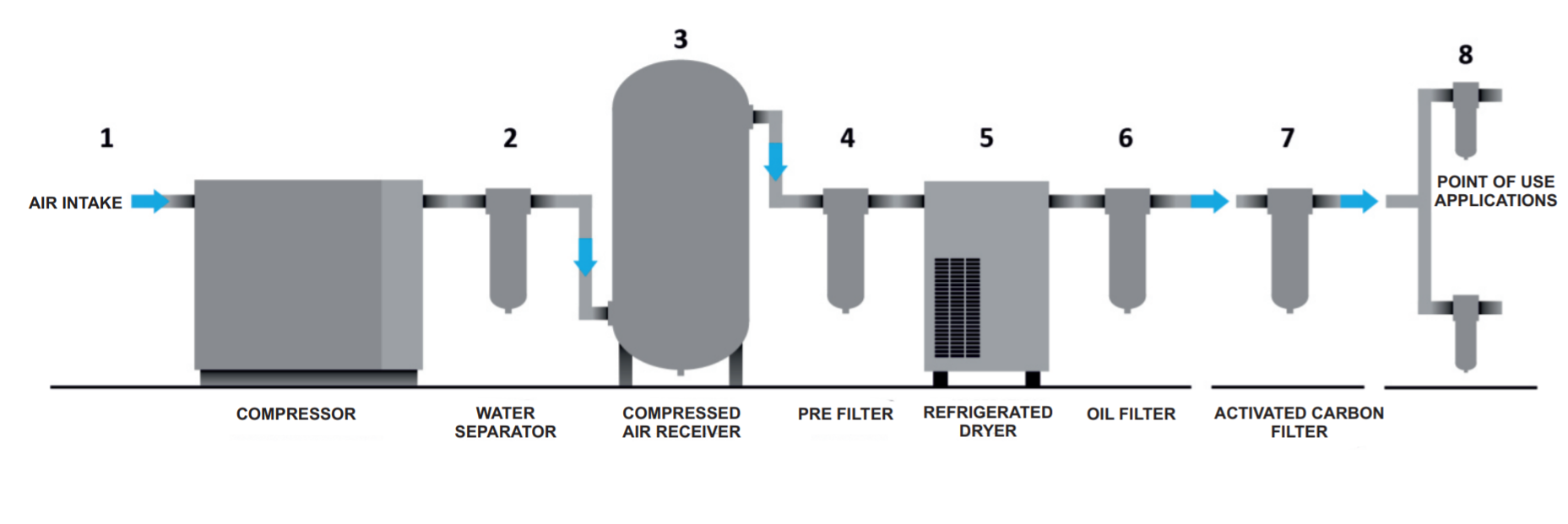

Warm Compressed air enters into the air to air heat exchanger, where it is precooled by outgoing cold refrigeration air. Pre-cooling makes it possible to use a similar "more economical" refrigeration unit. Then the pre-cooled air enters into the Freon Heat Exchanger, where it is cooled down to +3o C. At thsi cool temperature, moisture condenses into liquid droplets, which are removed from air stream by a very efficient demister and automatically drained by an Automatic Drain Valve. The cold dry compressed air passes back through the secondary side of the Air to Air Heat Exchanger, where it is re-heated by the incoming warm air. Reheating the outgoing compressed air increases temperature by heat with incoming warm air.

The dry air coming out from the air dryer is ready to use for instrumentation and process air applications.

Salient Features

- Compact design

- Low Pressure Drop

- Power Saving

- High Quality Finishing

- More Reliability

- Ease of Installation

- Environment Friendly

- Reduced Maintenance

- Constant dew point at all varying load

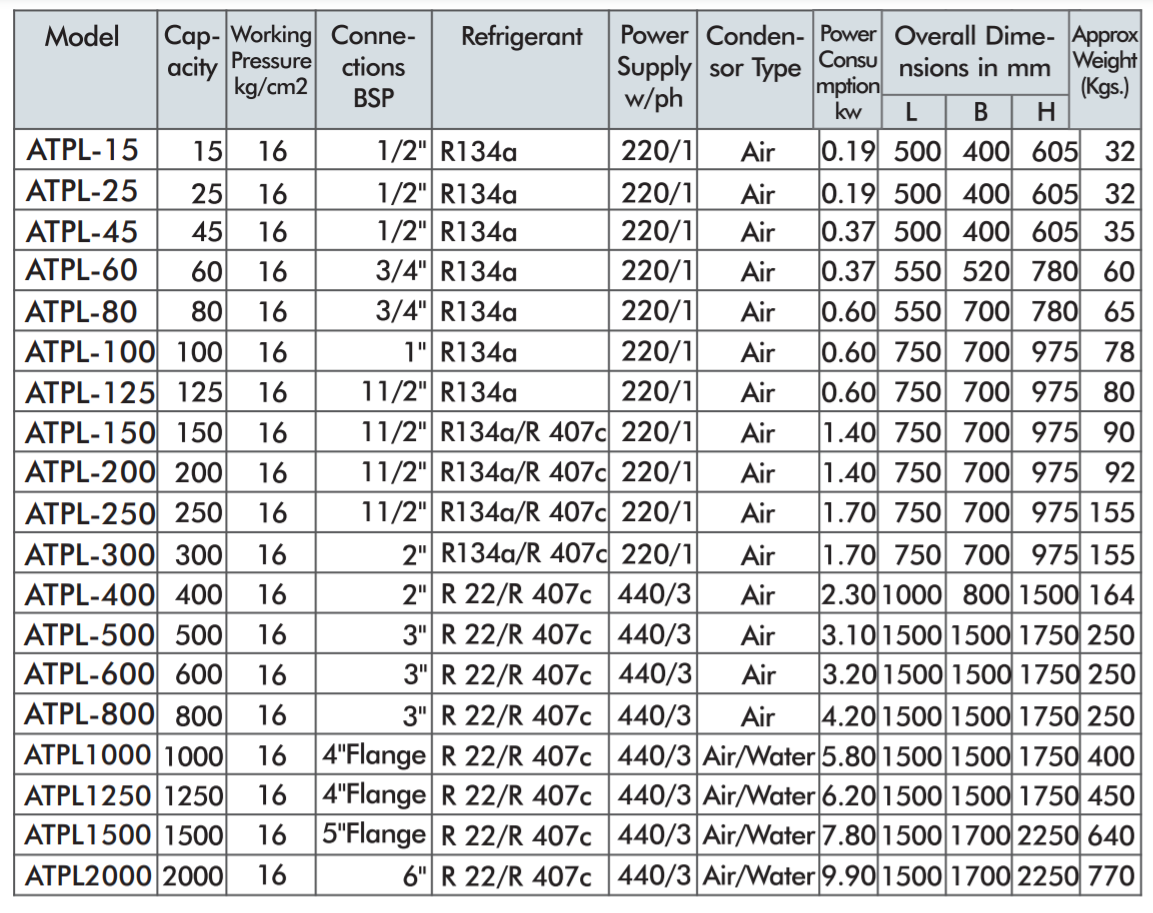

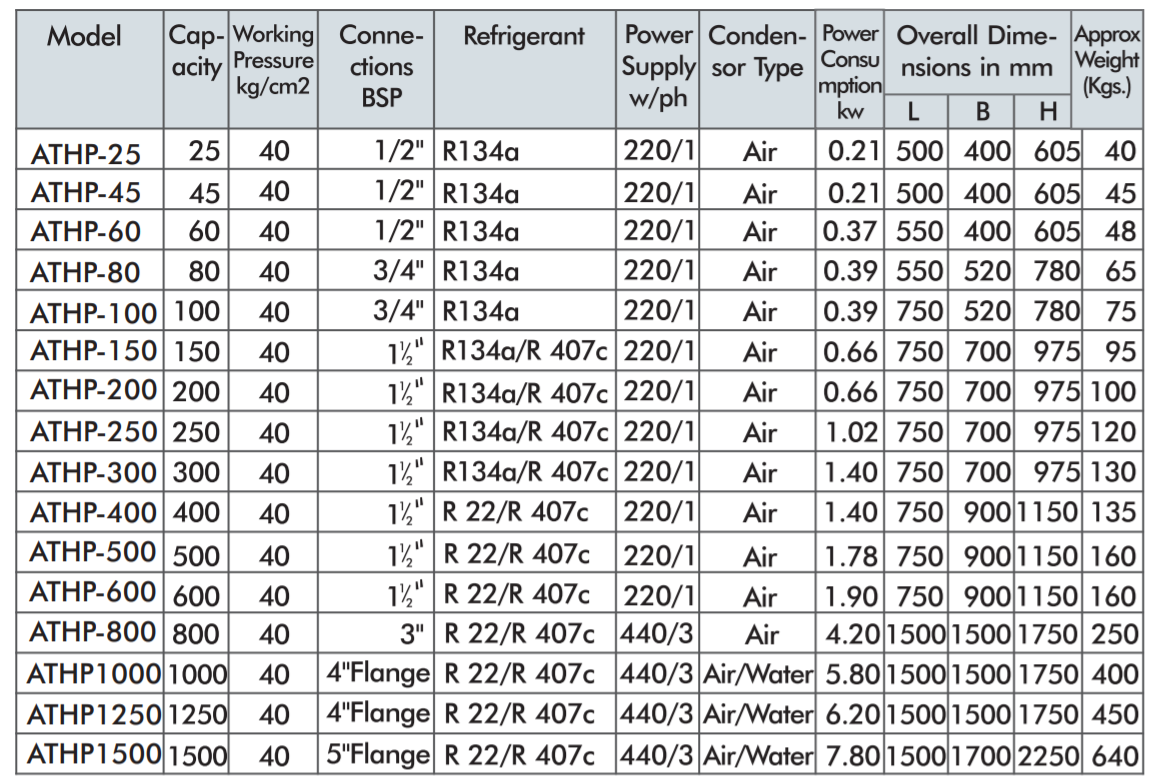

Technical Specification

Refrigerated Air Dryers (ATPL Series)

Refrigerated Air Dryers (ATPL Series)

Flow Diagram