How On-Site Nitrogen Generation Saves Businesses Time and Money

An on-site nitrogen generator is a system that produces nitrogen gas from ambient air through a process of separating nitrogen from other gases, particularly oxygen. These systems are typically installed at industrial sites to provide a continuous supply of nitrogen for various processes, removing the need to rely on bulk nitrogen deliveries or storage tanks.

There are two primary types of on-site nitrogen generators:

1. PSA (Pressure Swing Adsorption) Nitrogen Generator

- How it works: PSA generators use adsorbent materials, such as carbon molecular sieves (CMS), to trap oxygen and other gases while allowing nitrogen to pass through. The process involves alternating between pressurizing the air and then depressurizing it to release trapped gases, providing a consistent flow of nitrogen.

- Purity levels: PSA systems can achieve nitrogen purity levels between 95% and 99.999%.

- Applications: Ideal for industries requiring high-purity nitrogen, such as electronics, food packaging, Oil & Gas Generation, Manufacturing, Automotive, Mining and pharmaceuticals.

2. Membrane Nitrogen Generator

- How it works: Membrane generators use semi-permeable membranes to filter out oxygen and other gases, allowing nitrogen to pass through. As compressed air moves through the membrane fibers, oxygen and water vapor permeate through the walls of the membrane, while nitrogen is retained.

- Purity levels: Membrane systems typically provide nitrogen purity between 90% and 99.5%.

- Applications: Suitable for industries like oil and gas, marine applications, and general manufacturing, where lower purity levels are acceptable.

There are numerous applications for On Site Nitrogen Generator as follows :

Applications of On-Site Nitrogen Generators:

- Food and beverage: To preserve freshness in packaging, prevent oxidation, and extend shelf life.

- Pharmaceuticals: In packaging and to maintain sterile environments.

- Electronics manufacturing: For soldering and other processes requiring inert atmospheres.

- Chemical processing: As an inert gas to prevent combustion or unwanted chemical reactions.

- Oil and Gas/Power Generation:For mechanical gas seal inerting, Onshore/Offshore, etc..

- Automotive and Mining: For extending tyre life and tyre filling and in mining for controlling lower explosive limits and to control blasts in mines.

Businesses that invest in on-site nitrogen generators can benefit from long-term cost savings, operational efficiency, improved safety, and environmental sustainability. Typical benefits of on siteNitorgen Generators as follows

1. Cost Savings

- Elimination of cylinder or bulk nitrogen deliveries: One of the major benefits is the reduction or elimination of the need to purchase bottled or bulk nitrogen. This saves on gas purchase costs, delivery fees, and the logistical issues related to nitrogen supply chains.

- Lower operational costs: Once installed, on-site nitrogen generators have lower long-term operational costs compared to continually buying nitrogen from suppliers. The system uses only ambient air and electricity to produce nitrogen, leading to consistent cost savings.

- No rental fees for tanks: With on-site production, businesses no longer need to rent nitrogen tanks or deal with potential tank handling fees.

2. Continuous and Reliable Supply

- Uninterrupted nitrogen production: Businesses are no longer dependent on external deliveries. With on-site generators, companies can produce nitrogen whenever needed, ensuring a continuous and reliable gas supply. This helps avoid disruptions in production due to delayed deliveries or supply shortages.

- Customizable output: On-site systems can be tailored to provide the exact nitrogen purity and volume required by the business, ensuring optimal use of resources.

3. Improved Operational Efficiency

- Immediate availability: On-site nitrogen generation provides businesses with instant access to nitrogen at any time. There is no waiting for deliveries or dealing with storage and inventory management.

- Reduction of downtime: Production processes can continue without interruption, as nitrogen is always available on demand. This minimizes downtime that may occur when waiting for nitrogen supplies.

- Minimal maintenance: Once installed, nitrogen generators generally require low maintenance, reducing the burden on the operations team.

4. Safety and Environmental Benefits

- Reduced risk of handling high-pressure cylinders: With on-site nitrogen production, businesses reduce the need to handle and store high-pressure nitrogen cylinders, which can pose safety risks.

- Lower carbon footprint: On-site generation reduces the environmental impact associated with the transportation of nitrogen gas by trucks. This reduces the business’s overall carbon footprint.

- No hazardous waste: Unlike nitrogen in cylinders, which may require special disposal considerations, on-site nitrogen production results in no hazardous waste or by-products.

5. Customization for Specific Business Needs

- Tailored nitrogen purity levels: Different industries and applications require varying levels of nitrogen purity. On-site nitrogen generators can be configured to produce nitrogen with purity levels between 90% and 99.999%, depending on the specific needs of the business, such as in food preservation, electronics manufacturing, or pharmaceuticals.

- Flexible output capacity: Businesses can scale their nitrogen production to match their needs, adjusting output based on demand, without worrying about over-purchasing gas in bulk or dealing with stockpiling.

6. Enhanced Control and Independence

- Increased autonomy: On-site nitrogen generators provide businesses with control over their gas supply, reducing dependence on third-party suppliers.

- Predictable production costs: Since businesses are producing their own nitrogen, they gain better visibility and control over the costs of nitrogen production, leading to better financial planning and management.

- Avoiding price fluctuations: By producing nitrogen on-site, businesses are shielded from market price fluctuations that may affect the cost of bulk nitrogen supply.

7. Scalability and Flexibility

- Modular systems: Many on-site nitrogen generation systems are modular, allowing businesses to expand or reduce nitrogen production capacity as needed. This flexibility ensures that businesses can scale their operations efficiently as their nitrogen demands grow.

- Adaptability for various industries: On-site nitrogen generators can be used in a wide range of industries, including food packaging, pharmaceuticals, electronics, automotive, chemical processing, and oil and gas, making them versatile and adaptable for different business applications.

8. Short Payback Period

- Fast return on investment (ROI): The initial capital investment in an on-site nitrogen generator is often recouped quickly due to the significant savings on nitrogen purchase and delivery costs. Many businesses experience a payback period of just one to two years, after which the cost savings continue to accumulate.

9. Compliance with Industry Regulations

- Consistent nitrogen quality: On-site generators provide consistent nitrogen quality and purity, which is crucial for industries with strict regulatory requirements, such as food production and pharmaceuticals. Maintaining high nitrogen purity levels ensures that businesses comply with industry standards and regulations.

To summarize, the ability to produce nitrogen on demand, without reliance on external suppliers, gives businesses greater control over their processes and enhances their overall productivity.

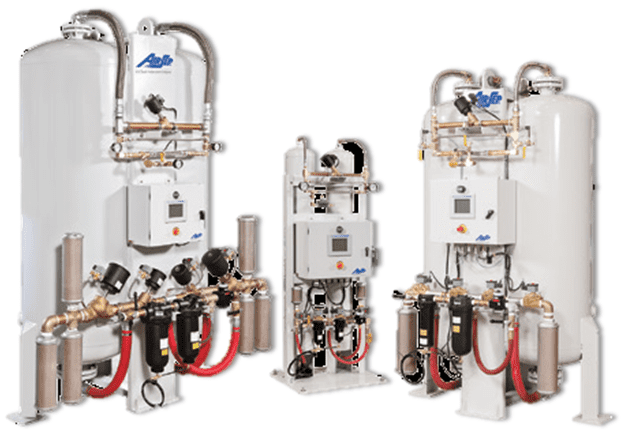

Why Choose AIROX’s PSA NITROGEN GENERATOR….

AIROX Technologies' nitrogen generators offer efficient on-site nitrogen production with purity levels up to 99.999%. They help businesses reduce costs by eliminating the need for bulk nitrogen deliveries and lowering operational expenses, as they only require ambient air and electricity. With customizable output and minimal maintenance, these systems ensure continuous, reliable nitrogen supply tailored to specific needs. AIROX nitrogen generators are energy-efficient and feature scalable designs, allowing businesses to expand production as demand grows. Offering a fast return on investment, AIROX nitrogen generators are an ideal solution for improving efficiency, safety, and sustainability in various industries.

Key Benefits:

- High nitrogen purity (up to 99.999%)

- Cost-effective with low operational expenses

- Customizable output for specific needs

- Energy-efficient and low maintenance

- Scalable design for growing demands

AIROX Technologies’ nitrogen generators are a smart, sustainable choice for businesses aiming to optimize their nitrogen supply.