PSA Nitrogen Systems

- PSA Nitrogen systems generate a continuous flow of nitrogen at desired concentrations for various commercial markets.

- Produce nitrogen with an AirSep nitrogen plant with 99.9-99.99% product concentrations.

- Any AirSep gas generating plant can be designed/customized for a wide range of applications and containerized options are available for easy installation.

- AirSep nitrogen plants are cost-effective, economical, and power-efficient, requiring just enough amounts of energy to power up the nitrogen compressor which in turn supplies air to the system.

Features:

- Airox Nitrogen Generators eliminate the expense, inconvenience, hazardous handling, and storage problems often associated with purchased liquid or high pressure cylinder nitrogen.

- The standard models Airox offers are the most efficient and reliable generators available today. With their proprietary mufflers, these units also achieve the lowest sound levels in the industry.

- Fully automatic, the generators require no specialized operating personnel. Simply connect an air compressor or central air supply to the generator and your application or nitrogen distribution system to the generator’s nitrogen receiver.

- Then connect the powercord to a grounded electrical outlet, turn the unit on, and set your nitrogen delivery pressure. A simple on-off switch supplies nitrogen whenever you need it.

Advanced Features and Controls:

Control and Monitoring

- 5.5” multi-color touchscreen operation interface

- Nitrogen concentration measured by ultrasonic technology,

- which eliminates regular calibration or cell replacement

- Data logging

- Remote monitoring capability

- Multi-level secured access for supervisory control

- Multi-language option

- Alarm and process parameters notification via email

- Visual recommended service maintenance reminders

- Parameters display option in metric or imperial units

- Real time trends of process parameters

- General maintenance guidelines

Specifications:

| Sr. No | Model | Part Number | LPM | SCFH Nitrogen Flow1 | Nm3/hr* | 7.6 barg SCFM Feed Air @ 110 psig | Nm3/min | Gal Nitrogen Receiver | Liter |

|---|---|---|---|---|---|---|---|---|---|

| 1 | N2–AS-D+ | NGAS097-8 | 200 | 450.00 | 12.00 | 21.00 | 0.55 | 120.00 | 450.00 |

| 2 | N2–AS-E | NGAS103-8 | 429 | 979.00 | 25.74 | 46.00 | 1.21 | 120.00 | 450.00 |

| 3 | N2–AS-G | NGAS104-8 | 715 | 1634.00 | 42.95 | 70.00 | 1.84 | 290.00 | 1100.00 |

| 4 | N2–AS-J | NGAS105-8 | 1450 | 3311.00 | 87.04 | 142.00 | 3.73 | 400.00 | 1500.00 |

| 5 | N2–AS-K** | NGAS106-8 | 2116 | 4823.00 | 127.00 | 242.00 | 6.36 | 660.00 | 2500.00 |

| 6 | N2–AS-L** | NGAS107-8 | 3075 | 7020.00 | 184.50 | 301.00 | 7.91 | 660.00 | 2500.00 |

| 7 | N2–AS-N** | NGAS092-8 | 4383 | 10012.00 | 263.00 | 452.00 | 11.88 | 1060.00 | 4000.00 |

| 8 | N2–AS-P** | NGAS093-8 | 6183 | 14097.00 | 371.00 | 654.00 | 17.19 | 1060.00 | 4000.00 |

| 9 | N2–AS-Q** | NGAS109-8 | 7983 | 18228.00 | 479.00 | 849.00 | 22.32 | 1550.00 | 5800.00 |

| 10 | N2–AS-R** | NGAS110-8 | 11000 | 25122.00 | 660.00 | 1166.00 | 30.65 | 1550.00 | 5800.00 |

| 11 | N2–AS-W** | NGAS111-8 | 15116 | 34494.00 | 907.00 | 1601.00 | 42.09 | 1550.00 | 5800.00 |

| 12 | N2–AS-Z** | NGAS122-8 | 19572 | 44671.00 | 1174.32 | 2177.00 | 57.23 | 2560.00 | 9700.00 |

Benefits Of Nitrogen Generators:

Control and Monitoring

- Purity Control. Set the purity level that you need and only pay for that purity.

- Increased Safety. No delivery, storage or movement of high-pressure cylinders.

- Cost Savings. Monthly investment cost is less than buying bottles/liquid oxygen. Payback is often two years or less. You save up to 80% on the cost of the nitrogen as compared to purchasing bulk or bottled nitrogen

- Environment. No reportable transportation to your site. No need to bleed-off/vent

- Nitrogen has a very low boiling point and is continuously evaporating when supplied as liquid in bulk or Dewars.

- If you already have an air compressor, you're halfway there! Hooking up a nitrogen generator to an existing air compressor installation can be easy.

- A constant supply is assured, so you'll never have to worry about a delivery not arriving on time - which decreases any potential of downtime.

- Save space & minimize risk and handling errors; no need for gas bottles or liquid nitrogen tanks in your workspace.

- Simplify administration to save time & money with no weekly deliveries to manage.

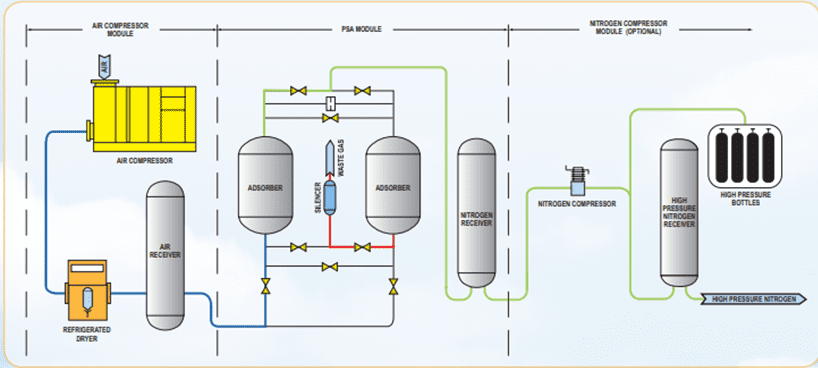

How does PSA Nitrogen Systems Works?

- The Vessels and sieves are taken from AirSep is the world leader in Pressure Swing Adsorption (PSA) technology.

- Airox Nitrogen Generators and Nitrogen Plants use at least two vessels filled with carbon molecular sieve as adsorbers.

- As compressed air passes through one of the adsorbers, the molecular sieve adsorbs the oxygen.

- This allows the remaining nitrogen to pass through and exit the adsorber as a product gas.

- Before the adsorber becomes saturated with oxygen, the inlet air flow switches to the second adsorber.

- The first adsorber is now regenerated by desorbing the oxygen through depressurization and purging it with nitrogen.

- The complete cycle is then repeated.

- Under normal operating conditions, the molecular sieve is completely regenerative and will last indefinitely

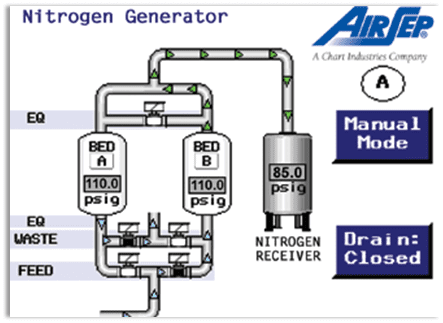

AirSep PSA Control Systems

- AirSep Standard Generator models N2-AS-D+ through N2-AS-Z are equipped with a NEMA 4 HMI touchscreen control panel with an integrated nitrogen monitor.

- The touchscreen provides a normal start-up system, monitors/controls the operation of the process valves, monitors signals coming from the pressure transducers, and provides an alarm system, as well as a fail-safe shutdown mode.

- This control panel also features diagnostic capabilities and Ethernet access for remote monitoring of process parameters.

- The various color screens are easy to follow, as the user-friendly interface maintains a consistent template design.

.png)

Typical Application

Oil & Gas/Power Generation

- Onshore / Offshore.

- Major Gas Supply Company Project Developments:

- Mechanical Gas Seal Inserting

- Chemical and LNG Tanker Trans-Ocean Shipments

- Oil & Gas High Pressure Tank & Piping-Works Testing / Re-Certification

- Enhanced Oil Recovery (EOR)

Manufacturing

- Cutting/Brazing/Soldering/Heat Treatment

- Electrical Storage/Transformers and Assembly

- High Pressure Plastic Injection Molding

Food & Beverage

- Modified Atmosphere Packaging (MAP)

- N2/CO2 Gas Mix Beer Drafting/Wine Bottle Capping

- Controlled Atmosphere (CA)/Fruit Storage

Automotive

- Tire Inflation

Mining

- Control of Lower Explosive Limits (LEL)